General

AXRY-NGX bearings are double-direction, screw-on precision bearing units ready for installation and intended for highly rigid applications, for example for rotary tables or milling heads.

AXRY-NGX bearings are double-direction, screw-on precision bearing units ready for installation and intended for highly rigid applications, for example for rotary tables or milling heads.

The bearing absorbs axial and radial forces and tilting moments backlash-free.

AXRY NGX bearings offer optimum speed, rigidity and life time in the available space. The bearings are greased as standard with a special grease according to DIN 51825-KPH-C1N-30.

. Other greases or ungreased bearings are available on request.

Generation AXRY-NGX

myonic bearings of the generation NGX were developed from the consistent optimisation and further development of the AXRY-EX series, and include numerous improved features:

■ Increased stiffness values

■ Increased load ratings

■ Increased life time

■ Axial and radial lubrication via the outer ring

■ Optional, radial lubrication via the inner ring (-SBI)

■ Assembly possible without axial washer (can be integrated directly into the table)

■ Connection dimensions H1 and H2 up to and including size 460 restricted as standard

Of course, all variants, restricted radial and axial runout, restricted height tolerances H1/H2 (for sizes 580 and 650) and also customer-specific bearing adjustments, are available without restriction for the NGX bearings.

Generation AXRY-NGX-SBI

Generation NGX-SBI myonic bearings have the same functions as the NGX series, but have been dimensioned for outer ring rotation. NGX-SBI is characterised by the following improved features:

■ Increased stiffness values

■ Increased load ratings

■ Increased life time

■ Radial lubrication via the inner ring

■ Assembly possible without axial washer (can be integrated directly into the table)

■ Connection dimensions H1 and H2 up to and including size 460 restricted as standard

For the AXRY-NGX-SBI series, all variants, restricted radial and axial runout, restricted height tolerances H1/H2 (for sizes 580 and 650) and also customer-specific bearing adjustments, are available without restriction for the NGX bearings.

Bearing structure

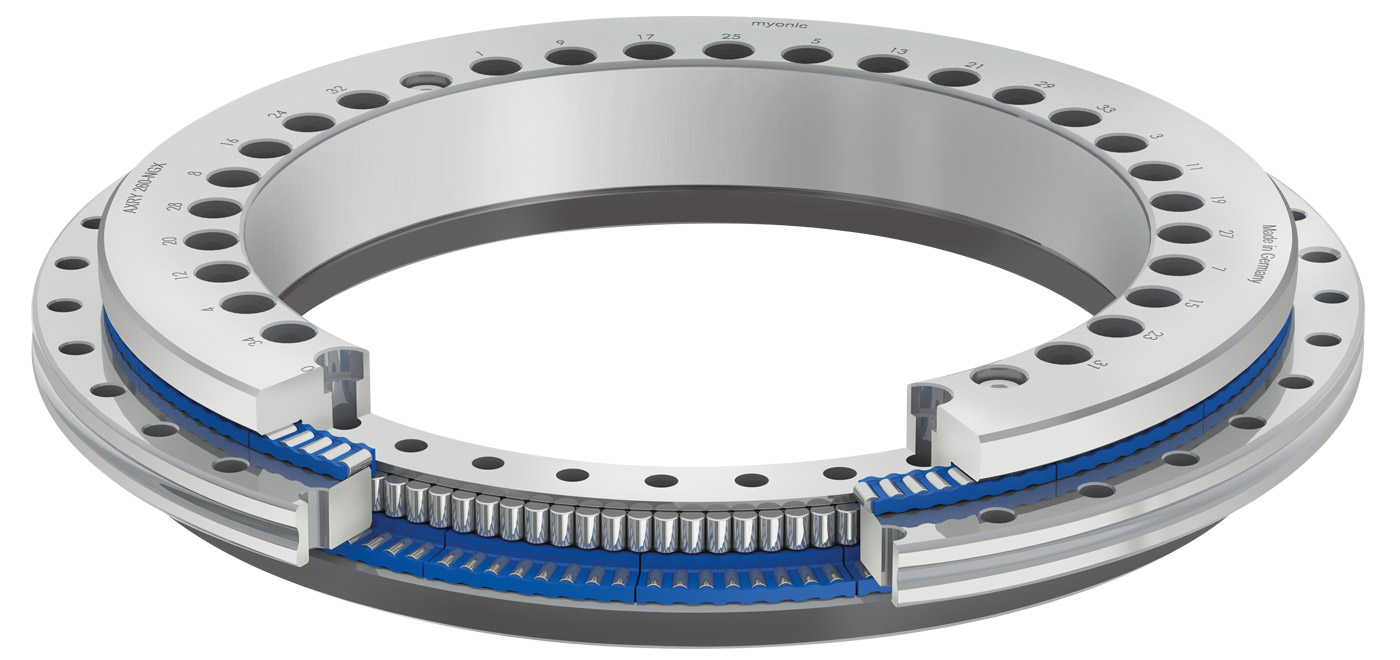

AXRY-NGX (NGX-SBI) bearings consist of three rings: an inner ring, the outer ring and an axial washer. The inner ring bore is manufactured to produce a fit with the appropriate tolerance.

The axial washer is unsupported in the area of the bore and is centred to the inner ring and fixed using fastening screws.

Fastening screws

The completely assembled bearing is held together using fastening screws. The axial washer is aligned with the inner ring at the factory. If the fastening screws have to be removed, they should only be replaced with fixing screws after the bearing has been completely screwed down. If the fastening screws are removed beforehand, the axial washer must be realigned so that no imbalance occurs in the system.